This is a list of most popular or subjectively best price/performance thermal paste compounds (or TIMs = Thermal Interface Materials) compiled for my personal quick reference and comparison. I thought it might be useful for others, as well. It is not considered complete at this stage and it probably never will be…

note: click on column headers to sort table by that particular column, click again to sort in reverse order

| Brand / Model ▲▼ | Thermal Conductivity [1] ▲▼ | Price [2] ▲▼ | Density [3] ▲▼ | Electrically Conductive [4] ▲▼ | Ease of Use [5] ▲▼ |

|---|---|---|---|---|---|

| Thermal Grizzly Carbonaut Pad [6] | 62.5 W/mK | $16.0 | – | Yes | Medium |

| Innovation Cooling Graphite Pad [6] |

35.0 W/mK | $10.0 | – | Yes | Medium |

| Thermal Grizzly Conductonaut | 73.0 W/mK | $15.0 | 6.24 g/cm³ | Yes [7] | Hard |

| Thermal Grizzly Kryonaut | 12.5 W/mK | $7.0 | 3.70 g/cm³ | No | Easy |

| Thermal Grizzly Hydronaut | 11.8 W/mK | $9.6 | 2.60 g/cm³ | No | Medium |

| Thermal Grizzly Aeronaut | 8.5 W/mK | $8.9 | 2.60 g/cm³ | No | Easy |

| Phobya LM Liquid Metal [10] | – | $5.25 | – | Yes | Hard |

| Phobya NanoGrease Extreme | 16.0 W/mK | $4.3 | 2.50 g/cm³ | No | Hard |

| Phobya HeGrease Extreme | 8.5 W/mK | $2.9 | 3.73 g/cm³ | No | Medium |

| Phobya HeGrease Standard | 6.0 W/mK | $1.7 | 2.50 g/cm³ | No | Easy |

| Thermalright Silver King | 79.0 W/mK | $13.0 | 6.77 g/cm³ | Yes [8] | Hard |

| Thermalright TFX | 14.3 W/mK | $6.5 | 2.60 g/cm³ | No | Hard |

| Thermalright TF8 | 13.8 W/mK | $5.0 | 2.90 g/cm³ | No | Easy |

| Thermalright TF6 | 12.5 W/mK | $3.5 | 3.60 g/cm³ | No | |

| Thermalright TF4 | 9.5 W/mK | $4.0 | 2.70 g/cm³ | No | Easy |

| OurGD GD007 | 6.8 W/mK | $2.7 | 2.50 g/cm³ | No | |

| OurGD GD900-1 Silver | 6.0 W/mK | $1.9 | 2.50 g/cm³ | No | |

| OurGD GD900 | 4.8 W/mK | $0.25 | 2.30 g/cm³ | No | Easy |

| Noctua NT-H2 | – | $7.1 | 2.81 g/cm³ | No | Medium |

| Noctua NT-H1 | – | $4.8 | 2.49 g/cm³ | No | Medium |

| Arctic MX-4 | 8.5 W/mK | $2.5 | 2.49 g/cm³ | No | Medium |

| Arctic MX-2 | 5.6 W/mK | $1.0 | 3.96 g/cm³ | No | Easy |

| Arctic Silver 5 | 8.89 W/mK [11] | $3.8 | – | No [12] | Medium |

| Gelid GC-Extreme | 8.5 W/mK | $4.0 | 3.73 g/cm³ | No | Medium |

| Gelid GC-Pro | 7.0 W/mK | $2.2 | 2.80 g/cm³ | No | Medium |

| Gelid GC-Supreme | 4.5 W/mK | $1.1 | 2.55 g/cm³ | No | Medium |

| Gelid GC-2 | – | $1.1 | 2.80 g/cm³ | No | Medium |

| Corsair TM30 | 3.8 W/mK | $2.3 | 2.50 g/cm³ | No | |

| KingPin Cooling KPx | – | – | – | – | Hard |

| Cooler Master MasterGel Maker | 11.0 W/mK | $7.5 | 2.6 g/cm³ | No | Medium |

| Cooler Master MasterGel Pro | 8.0 W/mK | $3.5 | 2.6 g/cm³ | No | Medium |

| Cooler Master Extreme Fusion X1 |

9.5 W/mK | – | 2.6 g/cm³ | No | Medium |

| Cooler Master IC Essential E1 | 4.5 W/mK | – | 2.5 g/cm³ | No | Easy |

| Cooler Master IC Essential E2 | 3.5 W/mK | – | 2.4 g/cm³ | No | Easy |

| Innovation Cooling Diamond 7 Carat | 4.5 W/mK | $6.0 | – | No | Hard |

| LT-100 Liquid Metal Grease [9] | 128.0 W/mK | $7.0 | – | Yes [9] | Hard |

| Halnziye HY880 | 5.15 W/mK | $0.4 | – | No | Medium/Hard |

| Halnziye HY810 | 4.63 W/mK | $1.45 | – | No | Easy/Medium |

| PcCooler A1 [13] | 7.5 W/mK | $1.5 | – | No (?) | Easy |

| PcCooler A3 | 5.5 W/mK | $0.3 | – | No | Easy |

| ALSEYE T9+ | 13.0 W/mK | $4.45 | – | No | Medium/Hard |

| ALSEYE S880 [14] | 5.15 W/mK | $0.4 | – | No | Medium/Hard |

| ALSEYE S810 [15] | 4.63 W/mK | $1.15 | – | No | Easy/Medium |

- Data is provided as is – any corrections may be submitted in comments section below.

- If your product is not listed above, you may use our contact form or comment section below to submit it.

- While we try to be 100% accurate, in some cases data was not provided directly by original manufacturer, so they were obtained elsewhere from indirect sources (e.g. online shops product specifications).

NOTES

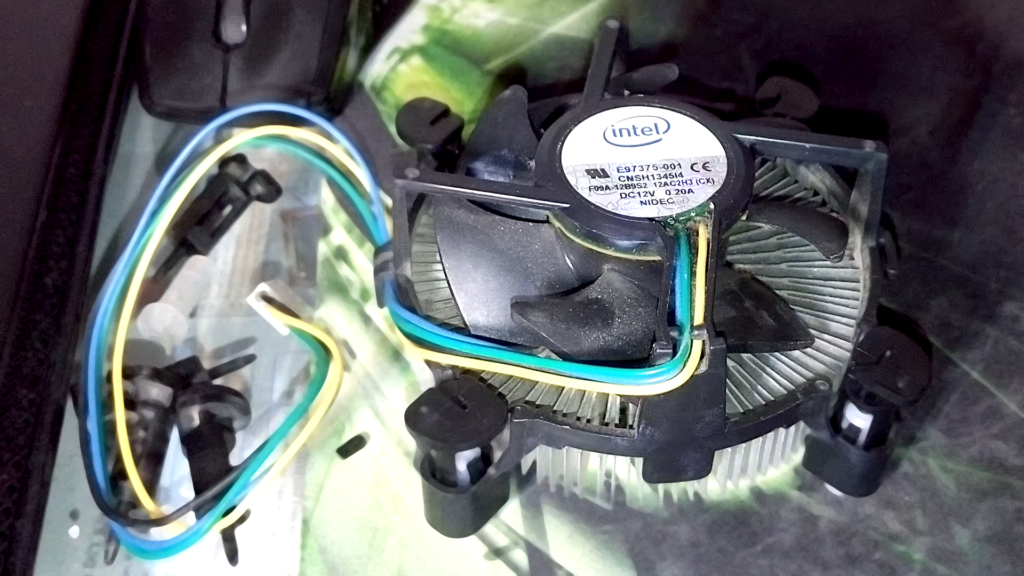

[1] Thermal Conductivity roughly translates to better performance overall. However, the relationship between temperature reduction and thermal conductivity is not exactly linear, and it may differ for different cases (CPU or GPU, air/water/passive cooling, low pressure (push-pins) or high pressure (back-plate + screws) HSF mounting systems). Additionally, in good cooling systems, large heatsinks or air flow usually compensates for TIM layer variance and results are only within couple of degrees difference (0.5 ~ 3.0 ° C) between low/mid and high-end solutions. Higher viscosity compounds and pads tend to fill-in large gaps more effectively, but may “fail” with microscopic ones in low-pressure mounting systems, effectively resulting in larger surface contact resistance and lower performance, despite material higher thermal conductivity itself.

[2] Price

for Pad: Price for approx. 30×30 mm size.

for Paste: Price for 1 gram in USD at the time of publishing. Approx price was derived from popular online shops including shipping. Price varies between shops, shipping location (delivery country/address) and amount (package size). Smallest available package was chosen to calculate equivalent price for 1 gram. Bigger (bulk) quantities/packages are more economical, but not attractive to most ordinary users and hobby or personal use.

[3] Density should not be confused with Viscosity (see [5] below). Denser compounds appear heavier per unit of volume.

[4] While most compounds claim to be electrically non-conductive and non-capacitive, some may act like parasitic capacitance, and you should pay attention and try to be careful not to spill it around sensitive (exposed) PCB paths and components.

[5] Easy of use is relative quality directly related to viscosity (in case of pastes) or ease of application (in case of pads). For pastes, higher viscosity compounds appear thicker and harder to spread (also see [1] above). Higher viscosity = harder to spread or clean/remove paste later. Ideally, you should put as little paste as possible (for example 0.001 inch / 0.025 mm), because excessive thermal paste layer actually prevents effective heat transfer from processor to cooler, since TIMs have much less thermal conductivity than aluminum and copper. In this regard, viscosity can greatly affect compound spreading and gaps filling ability. This phenomena may explain ‘break-in’ period some thermal compounds exhibit. For pads, some users reported how slippery pads are and that tiniest misalignment while installing HSF back can cause high temperatures.

[6] Pads come pre-assembled for many standard CPU/GPU chips. While thermal conductivity is higher and very close to liquid metal solutions, it’s thickness (Thermal Grizzly pad is 0.2 mm thick, Innovation Cooling pad is 0.125 mm thick) is very high and lowers the heat transmission compared to standard thermal compounds. As technology matures and allows for thinner pads, they may eventually outperform any conventional paste. Thermal pads cannot compensate well for surface height variation like the pastes do. Thermal pads are performing better in high-pressure HSF mount systems. This means that push-pins low-pressure mounting systems are in general not good candidates for pad applications.

[7] Liquid metal compound. Not suitable for < 10° C temperatures and sub-zero cryo cooling. Corrosive compound. Not suitable for aluminum heatsinks. May leave residue after removal.

[8] Liquid metal compound. Not suitable for < -3° C temperatures and extreme cryo cooling. Corrosive compound. Not suitable for aluminum heatsinks. May leave residue after removal.

[9] Liquid metal compound. Not suitable for < -30° C temperatures and extreme cryo cooling. Corrosive compound. Not suitable for aluminum heatsinks. May leave residue after removal. This compound comes from unknown or less-known manufacturer, claims some pretty high specifications against well-known competition, and has a very competitive price — however, results should be verified first by independent 3rd parties.

[10] Liquid metal compound. Data not provided by manufacturer. Corrosive compound. Not suitable for aluminum heatsinks. Phobya LM compound does not contain any toxic heavy metals such as mercury or lead. Non toxic, not flammable, not explosive, does not vaporize. Despite being liquid, this compound has a high contact tensions by adhesive forces and can not flow from contact surface when applied correctly. It is mandatory that only a very small amount (drop) is applied with a brush, barely covering the surface. If these instructions are being followed, the contact surface (e.g. CPU) does not need to be sealed, as compound cannot flow from surface even in systems with vertical mounting.

[11] Data extracted and converted from online store. Not provided by original manufacturer.

350000 W/m²K × 0.0000254 m = 8.89 W/mK

Note: Arctic and Arctic Silver brands are produced by different manufacturers.

[12] Not a conductor, but not a true insulator either.

[13] Silver content 25% (per manufacturer).

[14] Unoficially, it looks like rebranded Halnziye HY880.

[15] Unoficially, it looks like rebranded Halnziye HY810.

Which Thermal Paste Should I Buy/Use?

This question seems to be simple enough – depends on how deep your pockets are and how much money are you willing to spend. On the other hand, the answer is actually far more practical than that, if you understand couple of things about cooling performance and how it actually works.

First and foremost, there is no point of using high-end thermal compound solution with generic, lousy and loud stock cooler, hoping that that setup will outperform some other system using better cooler with larger fan (or no fan – passive heat-sink) with generic or cheaper thermal paste! While it is true that high-end thermal paste will better display it’s superior properties against low-end solutions using smaller or less-effective stock coolers (assuming theoretically equal TIM layers thickness and other variables), problem is the price you have to pay for at least 1.5 or 2 grams package (sometimes even more)!

High-end Thermal Paste vs Midrange / High-end Cooler (Heatsink + Fan)?

In my personal opinion, e.g. if you have a stock CPU cooler (GPU cooling solutions are nowadays usually tightly integrated with overall graphics card design), and you wish to improve your cooling performance (lower temperatures, reduce fan noise), the most logical step is to invest $15 in better cooler and average/mid-range/economical paste, instead of buying a high-end paste alone! If you are not too finicky about secondhand (used) coolers, you can get a really great one with larger effective surface area, many aluminum (or copper) fins, massive copper base and heat pipes, accompanied with lower RPM fan (lower RPM = lower noise). Or it may be a completely passive cooling solution. In any case, that is a better move than investing in an expensive thermal paste alone.

On the other hand, if you already have a great cooler and you are satisfied with it, or you are simply stuck with what you already have, but you still wish to improve efficiency of your system (reduce temperatures, fan noise and electricity bill), then by all means – go for high-end.

If you want the best possible performance, you should go with liquid metal* or modern graphite or carbon nano-tube pads** solutions. Both are electrically conductive. In case of liquid metal paste, you have to be delicate not to spill it around on other components or surrounding PCB. In case of a carbon pad, application is very simple, just make sure you pick up the right size.

* Liquid metal solutions are not suitable for beginners. They require special application procedure and removal at later stage usually leaves traces or damaged IHS surface. You must understand the risks involved before use.

** Pads may outperform low- and mid-range grease solutions, but individual experience may vary and in some cases high-end thermal grease compounds may outperform pads by a noticeable margin. High-pressure HSF mounting systems are recommended.

![Xiaomi App - How To Re-Install Stock Factory Version - How To Fix Corrupted Gallery App [no root]](https://tehnoblog.org/wp-content/uploads/2025/09/Xiaomi-Gallery-App-Code-Bugs-Artwork-1024x576.png)

3 Comments

Add Your CommentI am trying to find data on whether or not GD900 is electrically conductive as some claim it is and others that it is not. How did you come to the conclusion that it is not electrically conductive? Thanks.

Also, amazing list! I’m saving this :)

November 20th, 2020Hi, data was copied from manufacturer’s website product page, if I remember correctly. I know this is basic, but bare in mind that “thermal conductivity” (heat transfer capability property) has nothing to do with “electrical conductivity” (electrical current capability property), and it’s possible that some read “conductivity” as electrical, when in fact, it is not the same thing. There’s also GD900-1 Silver variant, but that’s not the regular silver in it, most likely oxidized particles to increase thermal conductivity.

I haven’t tested it personally to determine if it is really non-conductive or not, that requires a serious laboratory equipment and knowledge (physics / chemistry / electrical), because it is not so simple as you might think! Conductivity depends on several factors, such as applied pressure to material, layer thickness and temperature, not to mention unknown chemical composition of the “secret” materials used to create this particular compound.

I can’t find the website now, but have found that some sellers posted ingredients ratio for GD900:

– Silicone Compounds: 50%

– Carbon Compunds: 10%

– Metal Oxide Compounds: 40%

Note that not all Metal-Oxide Compounds are equally electrically conductive, and their properties greatly vary from above mentioned factors.

Also, I have found table with ASTM D150 test data:

– Test Frequency: 100 Hz

– Dielectric Constant: > 5.0

DC of 5 is solid in terms of insulation, so I guess it’s safe to assume it is not electrically conductive. Of course, there are better insulating materials. The test frequency of 100 Hz might seem too low, because computer hardware operates at much higher bus frequency, and I do not have any means to determine complex DC vs Frequency relationship.

* * *

In any case, any thermal compound material can be considered partially as electrically conductive (absolutely ideal electrical insulator does not exist!) and capacitive (CPU + Heatsink form a capacitor with insulator thermal grease placed in between), but if you put thin layer in between CPU or GPU (which usually do not share common heatsink), there is absolutely no reason to worry that it will “leak” to surrounding PCB and damage something. This is also why PCBs are protected with insulating layers on external surface sides, to minimize probability of short circuits in case of any contact with foreign objects.

If you plan to use it in other electronics projects, such as audio amplifiers and alike, where several transistors can share a common heatsink, then I don’t really know, maybe switch to another brand that is known for a fact that has sufficient and verified insulation, or use insulation pads (mica washers) in between.

November 20th, 2020Absolutely terrific reply! Thank you and consider me a new reader. Good stuff.

November 21st, 2020